The basics of the Master Production Schedule:

The result of a balancing act

Why do we discuss the basics?

In the past three years, I have asked different master planners what their definition of their role was, and I got the following answers in different industries:

- “I make weekly analyses on the backorders, the forecast errors and the inventories. I send these reports to my management and once a month we discuss it in the S&OP meeting.”

- “I handover batches that need to be produced and I follow up on the execution of those batches with the detailed schedulers.”

- “I make a plan where batches are produced as late as possible. We don’t want to keep inventories that we don’t need.”

These answers do not fully meet what one could or should expect from a master scheduler. Before we start discussing the different aspects in the upcoming posts, we need to assure the basics are set. So that is what we intend to do in this article!

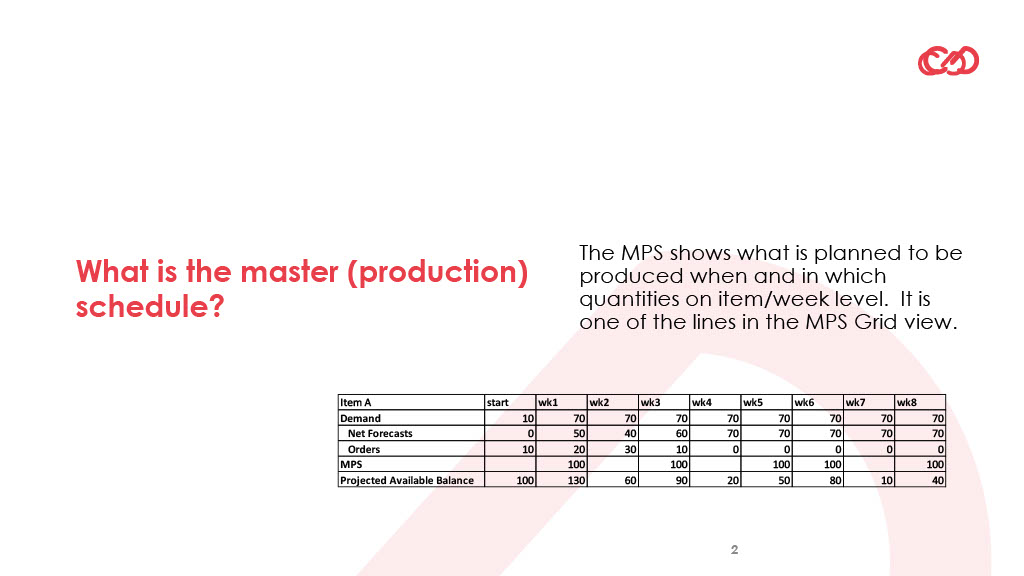

What is the master (production) schedule?

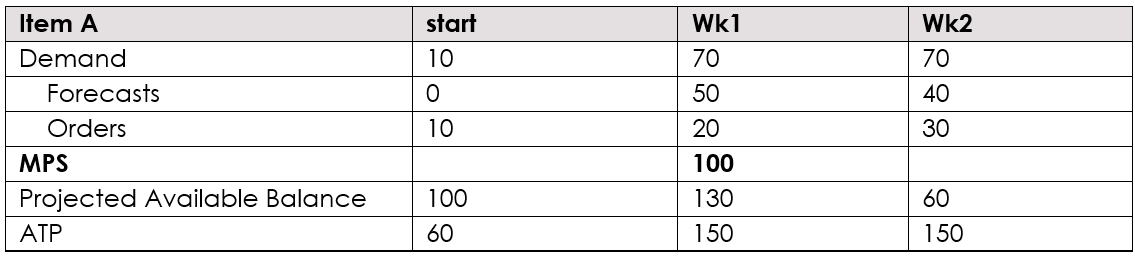

The master schedule is a grid, a table so to say. In that table, we see per item (on Item-level!), (at least) the following information:

- Time periods (very often weekly time periods)

- Demand (net forecasts, customer orders)

- Projected available balance

- Available-to-promise

- The master production schedule

The Master Production Schedule is one of the lines that are presented in the grid and shows what is planned to be produced when and in which quantities.

Very often, additional information is shown. This can be:

- Safety stocks

- Demand can be further split e.g., by ‘source’ of demand (per customer, location, customer type, …)

- Possibly dependent demand often generated by demand coming from distribution locations or other plants in the network generating a demand on this item

- Forecast consumption information (gross forecast, consumed forecast etc.)

- Days of inventory / coverage

Why do we make a master production schedule?

The master production schedule should allow us to:

- Assure the agreements that are made between sales and manufacturing are reflected. These agreements are typically made in the production plan on S&OP (Sales & Operations Planning) level where agreements are typically made on family/month level (versus the item/week level on which we make an MPS). Of course, there can be reasons to deviate and then the MPS can drive those discussions by providing a clear analysis on the causes for the deviation and aligning with the stakeholders on the best way to respond.

- Assure the customer service levels are maintained

- Assure we can make the most efficient and effective use of resources

- Manage inventories and / or backlogs at the desired levels

- Enable valid order promises

Each of these elements refers to one of the elements in what we call the ‘golden triangle’: service level, cost and inventory.

This sounds very nice and easy, and all these aspects are ‘important’. In reality, the planner will sometimes need to choose which of the above is ‘more important’ than the others and will need to make trade-off decisions.

- A planner might choose to make ‘most efficient and effective use of resources’ but this might be in conflict with the intention to also manage inventories or backlogs.

- In a very similar way, the planner might need to choose between ‘respecting agreements’ and managing service levels. In case the demand increases in an unexpected way, one of both elements can be impacted.

The Master Production Schedule is the result of a balancing act

It means that a good master production schedule is the result of well-thought-through choices. Those choices are a result of a balancing act, between the key elements of the golden triangle (cost, service level and inventory). It requires analysis, evaluation and decision-making.

It goes further than just ‘analyzing’ or ‘reporting’ or ‘minimizing inventories’. A good master production scheduler needs to realize trade-off decisions. The interests between the elements of the triangle (cost, service level, inventory) are naturally contradicting.

Assuring high service levels is very easy if you can hold a lot of inventory. It remains very easy even with low inventories if you have access to unlimited flexibility in your plant. If the plant asks how high they should jump whenever you tell them to jump, it is really not difficult to maintain low inventories and still keep your service levels up. The reality is typically different, and the plant will want to keep the costs under control. Planners also need to keep inventories under control while incorporating costs and maintaining service levels.

It is a true balancing act that requires a mature assessment of the situation. The planner needs to fundamentally acknowledge the impact each decision has on the three elements (service level, cost and inventory).

In some cases, planners might say:

- “Inventory is not very important and we don’t actively manage it”

- “Inventory is key and we should drive inventories down, that is our main task”

- “Our customers are key. We are here to serve our customers”

- “We need to assure we use the capa as agreed no matter what”

Such statements indicate the planner does not (yet?) incorporate all aspects. In a mature planning process, the planner will gain insight for himself, and create transparency to the different stakeholders. He will be able to:

- Show the proposed plan

- Show the degree to which this plan is in line with inventory targets

- Show the degree to which the resources are used in an efficient way

- Show the degree to which the service level can be maintained

- Show the degree to which previously made agreements can be respected

- Clarify why certain elements are negatively impacted, what the root cause is

The planner would also be able to indicate why he would believe this is ‘the best possible plan’ and what the impact would be for a possible alternative plan on the different elements.

The supporting tools

The different supporting tools allow the master production schedule to do this full assessment of the different elements in a systematic, disciplined and rational way. It would allow him to gather insights, and the planner can also use these tools to provide transparency towards the stakeholders.

Below you can find already an initial list but in the upcoming posts, we will discuss them in further detail:

- The RCCP (Rough Cut Capacity Plan)

- The DSI (Demand Supply Inventory) chart

- The comparison between the MPS and the S&OP plan

- The leading and lagging indicators

References

Apics, CPIM Part 1